Description

AW3209

Fasson® Coated Paper/AP104/60g White Glassine Liner (Back Printing)

Technical Specifications

- Surface Substrate: Semi – glossy white coated paper, super – calendered.

- Basis Weight: 80 g/m² ± 10% (ISO536)

- Thickness: 0.070 mm ± 10% (ISO534)

- Adhesive: General – purpose permanent acrylic emulsion.

- Liner: White glassine paper, super – calendered.

- Basis Weight: 60 g/m² ± 10% (ISO536)

- Thickness: 0.052 mm ± 10% (ISO534)

- Typical Adhesion Values (N/25mm):

- Initial Tack (st, st) – FTM 9: 14.0 or failure

- 20 – minute 90° Peel Adhesion (st, st) – FTM 2: 7.0 or failure

- 24 – hour 90° Peel Adhesion (st, st) – FTM 2: 8.0 or failure

- Temperature:

- Minimum Labeling Temp: 10°C

- Service Temp (24h after labeling): – 50°C ~ + 90°C

Thermal Transfer Label (Semi Gloss) Material:

This material has high paper strength and high surface glossiness , excellent printing effect . Suitable for various printing methods and ribbon printing, can meet the needs of printing or blank die-cutting product

| Product Code | Facestock | Liner | Adhesive |

| AW5209.2000 | Coated Paper/HP104 | 60 White Glassine, Back Printing Fasson® | Hot Melt Adhesive |

| AW3209.2000 | Coated Paper/AP104 | 60 White Glassine, Back Printing Fasson® | Acrylic Adhesive |

| AW4200K.2000 | Coated Paper/AP103 | 58 White Glassine, Back Printing A | Acrylic Adhesive |

| AW5200K.2000 | Coated Paper/HP103 | 58 White Glassine, Back Printing A | Hot Melt Adhesive |

| AW3288.2000 | Coated Paper/HP103 | 58 White Glassine, Back Printing Fasson® | Hot Melt Adhesive |

| Max Width(mm) | Min Sales Length (M) | Order Width (mm) | Order Length (M) |

| 2000 | 500 | 0.5 Sliting | 1000/2000 |

- Adhesive Performance: High initial and final adhesion, performs well on various packaging materials; meets FDA 21CFR 175.105, suitable for non – direct contact labeling of food, medicine, cosmetics.

- Applications: For semi – glossy color labels in promotion/industry, general – purpose and blank die – cutting; not recommended for small – volume labeling.

- Printing & Processing: Suits single/color printing (all processes); control ink viscosity; compatible with rotary/flat – bed methods; suitable for hot stamping; avoid excessive release force; test fine barcodes.

- Storage: 1 – year shelf life at 23±2°C, 50±5% RH.

Company Profile

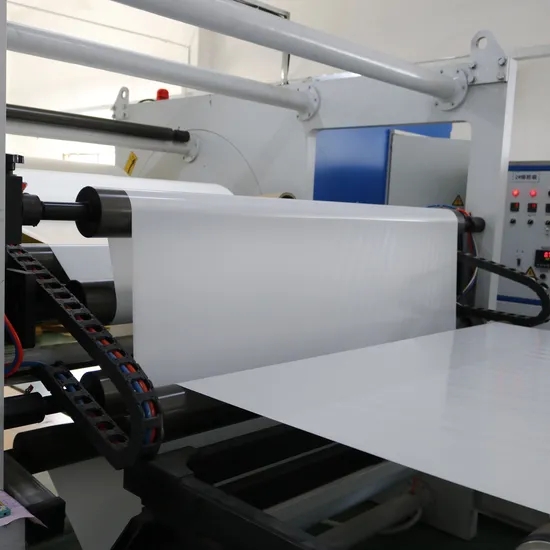

5000 square meters factory with over 30 production lines

diverse label materials in stock

high-speed coating machines for large capacity

strict quality control, and fast delivery

Custom Printing Design and Slitting Sizes are available

OEM Label Color and LogoStrict Quality Testing

Company Profile

FAQ

Q: Are you a factory or trading company?

R: We are the direct manufacturer with our own factory.

Q: Where is your factory? How can I visit there?

R: Our factory is located in Hunan Province, about 2 hours away from Guangzhou by railway.

Q: How can I get samples?

R: Free samples can be made within 2 days after confirmation, freight collect.

Q:Why the label will shifting after printing?

Q:I can not put the roll in the printer.

A:Check the core size & maximum diameter of printer first.

Q:Why the label not shows the color & content after printing?

A:Confirm your printer is inkjet printer (require ribbon to print) or thermal printer (heat sensitive),you can advise us your printer brand and item then choose the suitable material.

Q:Why is the content that I print looks not clear & fuzzy?

A:Use alcohol prep pad to wipe the printer head & the dust inside of machine first.

Q:How I can get free sample?

R:Send email or inquiry to us immediately!